EXTRUDABILITY CALCULATOR and PLOT

This calculator is designed to analyze the extrusion of power law shear-thinning fluids. We have shown that the flow of physically crosslinked hydrogels - which typically exhibit shear-thinning behavior - can be modeled at the shear-rates imposed during clinically-relevant injection processes. The viscosity (𝜂) of these materials is a function of shear-rate (𝛾̇) and can be expressed as 𝜂 = 𝐾𝛾̇n−1 where the consistency index (𝐾) and the shear-thinning index (n) describe the power law behavior. This calculator allows one to indicate relevant injection conditions and will then calculate the acceptable parameter space of 𝐾 and n for a material that is extrudable (i.e., injectable by a typical person). This parameter space is calculated and delineated using the following expression:

$$ K_{max} \leq \left(\frac{P_{max}R}{2L}\right) \left(\frac{\pi R^3}{Q_{min}}\right)^n \left(\frac{n}{3n+1}\right)^n $$

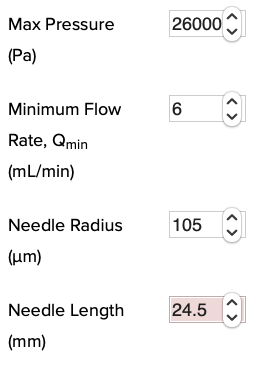

This calculator evaluates the extrudability of a material by analyzing the flow that would result from the desired operating conditions (i.e., maximum pressure applied by a healthcare professional) and material choice. Start by providing the maximum pressure, minimum flow rate, and geometry of your application. The fields are pre-populated to a pressure of 2.6 MPa (i.e., human force of 50 Newtons on a 5 mm diameter plunger), a flow rate of 6 mL/min, a needle diameter of 105 μm (27 gauge needle), and needle length 24.5 mm.

The figure will plot the equation shown above, delineating combinations of consistency index and shear-thinning index that correspond to power law fluids that satisfy your injection constraints. Combinations of 𝐾 and n that lie above the green line will require higher pressures or lower flow rates than those indicated, precluding injectability under your constraints. The blue line on the plot shows the shear rates that would result under your extrusion conditions.

This calculator allows you to indicate power law fluid parameters for your own materials. The power law parameters should be measured within the shear rates prevalent in your conditions (shown by the blue line on the plot) to prevent erroneous extrapolation. It will plot them on the figure and also calculate the relevant pressures and flow rates under your constraints. The pressure and shear rate are calculated at the minimum flow rate indicated, where the pressure should be less than the maximum pressure for an extrudable material. The flow rate and shear rate are also calculated at the maximum pressure indicated, where the flow rate should be greater than the minimum flow rate for an extrudable material.

The detailed derivation and validation of this model can be found in our manuscript (PDF).

Cite as: H. Lopez Hernandez, J. W. Souza, E. A. Appel, Macromol. Biosci. 2020, 2000295.